China Leading Supplier of Printing and Packaging Machinery & Materials

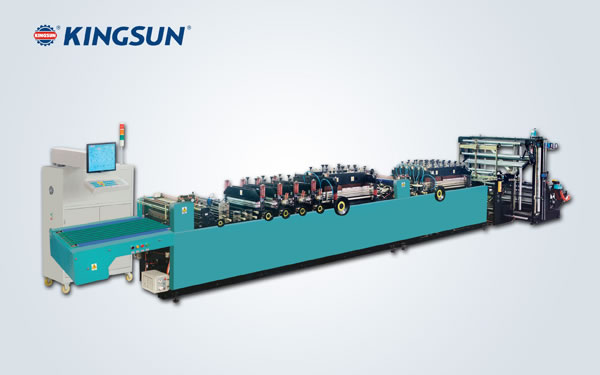

WKZD-500ZF Center Sealing Bag Making Machine

This series computer control center sealing bag making machine is suitable for making center seal bags, four side sealing bags, side sealing bags and plastic sachets.

More information about center sealing bag making machines

| Application scope | Material | various laminated films |

| Roll material | max width: 1,050mm max diameter: 600mm | |

| Adaptability of center sealing bag making machines | Bagging speed | 160 pcs/min (designed mechanical speed) approx. <30m/min |

| Bagging width | max width 500mm | |

| Bagging length | 50-400mm When the set length is above 400mm, this center sealing bag making machine will automatically transfer to multiple conveyances. | |

| Note: The actual bag making speed of our center sealing bag making machine may be a little lower, as a result of the difference of the bag type and material. | ||

| Warping mode | Main material | put the warp beam horizontally |

| Control | tension is automatically controlled by floating roller, a magnetic powder brake, displacement sensor | |

| Driving mode | Material-feeding traction mechanism | Driven by AC servo motor |

| Upper & lower press and sealing mechanism | AC motor drive or AC servo motor drive | |

| Functions of center sealing bag making machines | Heat seal | speed of heat seal, duration of heat seal, proportion of heat seal acceleration etc. (main servomotor) |

| Temperature | 0-300℃, contact-free automatic control, CRT displaying | |

| Automatic count | presetting is available | |

| Punching device | time can be preset, continuous or interval punching is available | |

| Working mode | printing, non-printing | |

| Mode of multiple conveyances | twice to six times conveyance | |

| Measurement for length | distance between color codes can be measured photo-electrically | |

| Optional functions of our bag making machines | feeding without movement, upper & lower regulating trimmer can be selected | |

| Message alert | failure of photoelectrical measuring device, low temperature, unwinding alarm, servomotor alarm, tension alarm, and auto-switch off the machine | |

| Power supply configuration | Servomotor for material-feeding mechanism | 1.0 kw x 1=2.0kw 1.5 kw x 1=1.5kw |

| AC motor for upper & lower press and sealing mechanism | 3.0 kw x 1=3.0kw | |

| Traction motor for unwinding mechanism | 0.55 kw x 1台=0.55kw | |

| Middle seal device | 2.4 kw x 1=2.4kw | |

| Lateral heat seal device | 4.8 kw x 3=14.4kw | |

| Plastic Middle-seal | 4.8 kw x 2=9.6kw | |

| Control system and others | 3kw | |

| Total: | Approx. 35kw | |

| Gas pressure | 0.6MPa (6kgf/cm2) | |

| Cooling water | Approx. 15L/min | |

| Gross weight of bag making machine | Approx. 5T | |

| Dimension (length × width × height) | 10,500×1,500×1,520mm | |

| Control mode | Adopts the industrial control equipment, CRT displayer | |

| Adopts double photoelectric control | ||

Kingsun Machinery Company is a specialized manufacturer and supplier of center sealing bag making machines. We have had over 20 years manufacturing experience for not only plastic bag making machines, but also die cutting machines, thermal film laminating machines, packing machines, and slitter rewinders, and more. All these products are manufactured strictly in accordance with the standards of ISO9001 International Quality Management System.

If you are interested in our products, please don’t hesitate to contact us. We are ready to serve you.