China Leading Supplier of Printing and Packaging Machinery & Materials

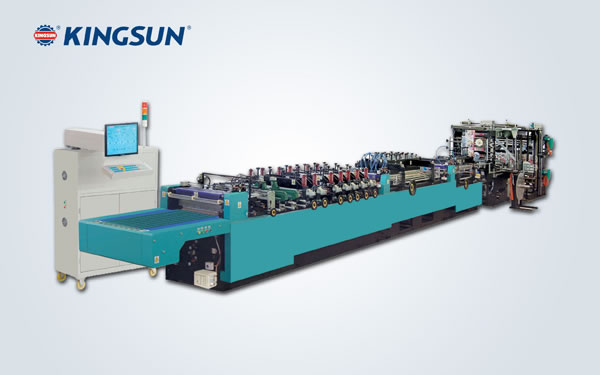

WKZD-600HK Series Three Side Sealing Bag Making Machine

WKZD-600HK series three side sealing bag making machine is suitable for making three side sealing bags, zipper bags, self-stand bags, and any other plastic bags and plastic sachet, etc. with any shape.

More detailed information about three side sealing bag making machines

| Application scope | Material | Various compound films |

| Roll material | max width: 1,240mm max diameter: 600mm | |

| Auxiliary material | max width: 180mm max diameter: 600mm | |

| Adaptability of three side sealing bag making machine | Bagging speed | 160 pcs/min (designed mechanical speed) approx. 30m/min |

| Bagging width | Maximum width 600mm | |

| Bagging length | 50-500mm, (multiple conveying device can be adopted when over-long).When the set length is above 320mm, this three side sealing bag making machine will automatically transfer to multiple conveyances. | |

| Note: The actual bag making speed of our three side sealing bag making machine may be a little lower, as a result of the difference of the bag type and material. | ||

| Unwinding method | Main material | put the warp beam horizontally, with V fold support, and pneumatically lock |

| Auxiliary material | put the warp beam horizontally, with triangle fold-plate | |

| Control | tension is automatically controlled by a floating roller, a magnetic powder brake, an encoder, displacement sensor etc. | |

| Driving mode | Material-feeding traction mechanism | Driven by an AC servo motor |

| Upper & lower press and sealing mechanism | AC motor drive or AC servo motor drive | |

| Functions of our computer control three side sealing bag making machine | Heat seal | speed of heat seal, duration of heat seal, proportion of heat seal, acceleration |

| Temperature | 0-300℃, contact-free automatic control, TFT displaying | |

| Automatic count | presetting is available | |

| Conveyance of finished bags | conveyance quantity is available | |

| Punching device | time can be preset, continuous or interval punching is available | |

| Working mode | printing, non-printing | |

| Mode of multiple conveyances | twice to six times conveyance | |

| Measurement for length | distance between color codes can be measured photo-electrically | |

| Optional functions of our bag making machines | feeding without movement, upper & lower regulating trimmer can be selected | |

| Message alert | failure of photoelectrical measuring device, low temperature, unwinding alarm, servomotor alarm, tension alarm, and auto-switch off the machine | |

| Power supply configuration | Servomotor for material-feeding mechanism | 1.0 kw × 2=2.0kw 1.5kw ×1=1.5kw |

| AC motor for upper & lower press and sealing mechanism | 4.0 kw × 1=4.0kw | |

| Traction motor for unwinding mechanism | 0.55 kw × 2=1.1kw | |

| Side heat seal device | 4.8 kw × 5=24.0kw | |

| Lateral heat seal device | 4.8 kw ×5=24.0kw | |

| Zipper heat seal device | 4.0 kw ×2 =9.6kw | |

| Auxiliary material tractions motor | 0.09kw x 2=0.18kw | |

| Control system and others | 3kw | |

| Total | Approx.70kw | |

| Gas pressure | 0.6MPa(6kgf/cm2) | |

| Cooling water | Approx.15L/min | |

| Gross weight of bag making machine | Approx.7T | |

| Outer dimension (length × width × height) | 13,700×2,625×1,860mm | |

| Control mode | Adopts the industrial control equipment; displayer is available | |

| Multiple photoelectric control | ||

Kingsun Machinery Company is an experienced manufacturer and supplier of three side sealing bag making machines. In addition to plastic bag making machines, we can also produce packing machines, printing machines, and more. All our products feature reliable quality and are provided at reasonable prices. They are extensively used in plastic processing industries, food and pharmaceutical packaging industries, book and periodical printing industries, and more. We wish you to be one of customers, too.